Woven wire mesh is a versatile material used in a variety of applications, from industrial to decorative. It is made by weaving wires together to create a mesh that is strong, durable, and flexible. There are several different types of woven wire mesh available, each with its own unique characteristics and properties.

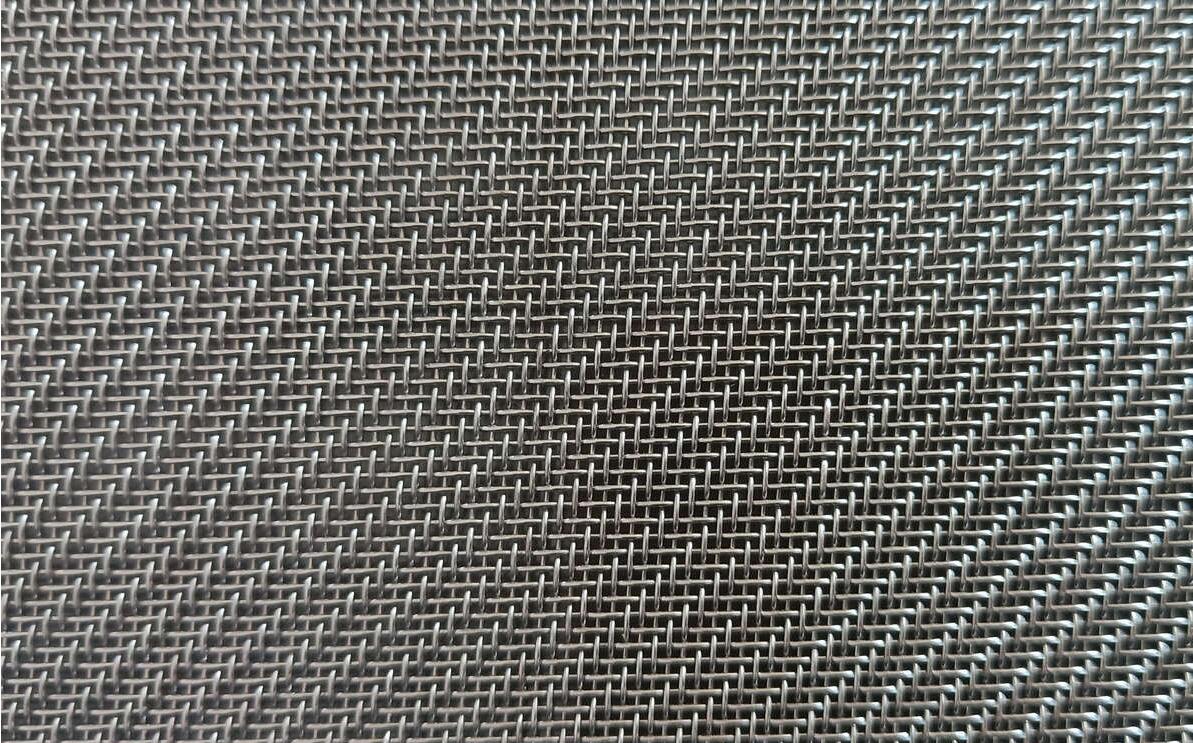

Plain weave mesh

Plain weave mesh is the most common type of woven wire mesh. It is made by weaving wires in an over-and-under pattern, with each wire passing over one and under the next. The result is a mesh that is strong, durable, and easy to work with. Plain weave mesh is used in a variety of applications, including filtration, screening, and separation.

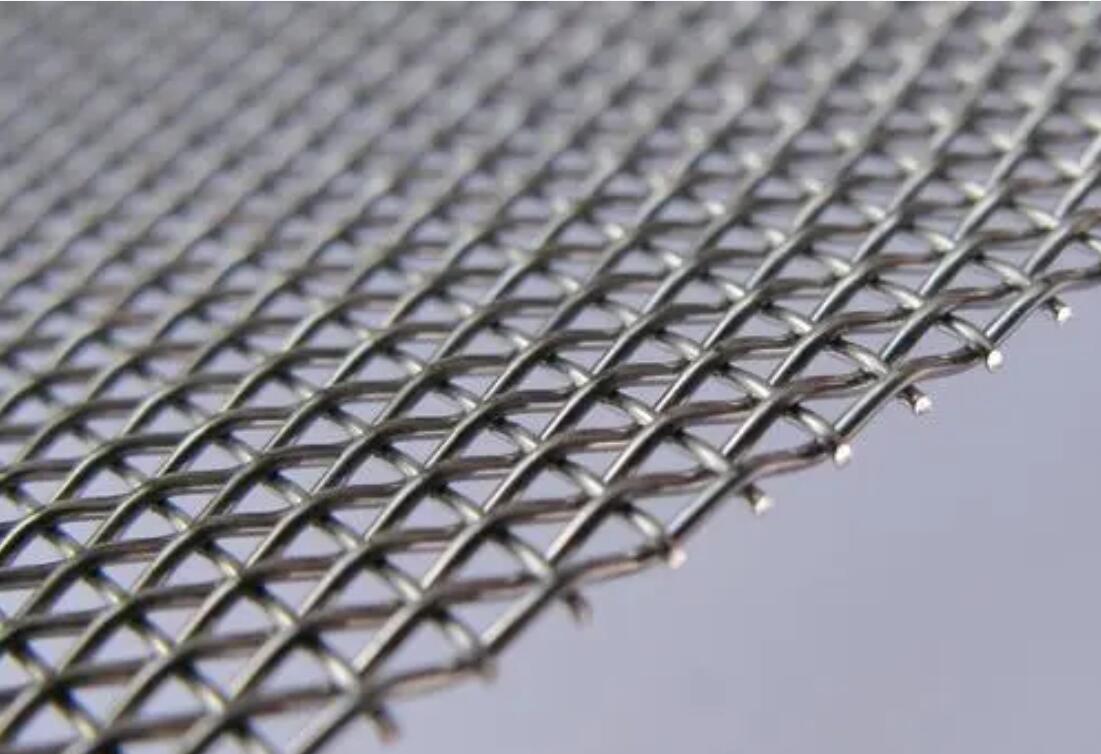

Twill weave mesh

Twill weave mesh is similar to plain weave mesh, but with a more complex weave pattern. The wires are woven in a diagonal pattern, which makes the mesh stronger and more flexible than plain weave mesh. Twill weave mesh is commonly used in applications where strength and flexibility are important, such as in the manufacture of conveyor belts and screens.

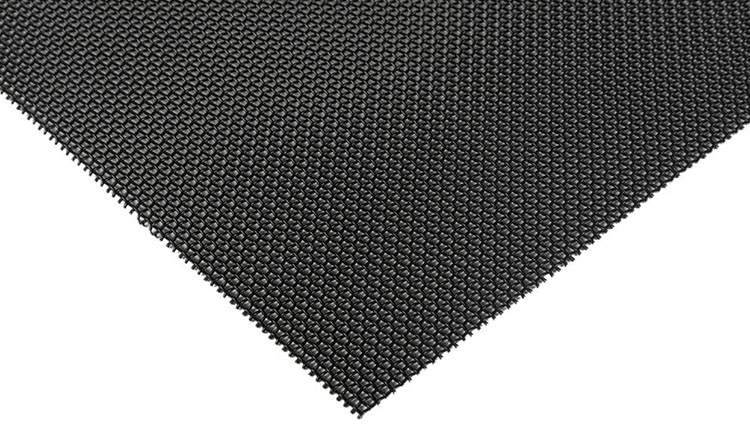

Dutch weave mesh

Dutch weave mesh is made by weaving wires in a pattern that is similar to twill weave mesh, but with a different wire diameter for the warp and weft wires. The result is a mesh that has a tighter weave on one side and a looser weave on the other. Dutch weave mesh is commonly used in applications that require high filtration accuracy, such as in the manufacture of oil and gas filters.

Welded wire mesh

Welded wire mesh is made by welding wires together at their intersections. The result is a mesh that is strong, durable, and easy to work with. Welded wire mesh is commonly used in construction, fencing, and agriculture.

Knitted wire mesh is made by knitting wires together using a special machine. The result is a mesh that is flexible, durable, and easy to work with. Knitted wire mesh is commonly used in applications that require a high level of filtration, such as in the manufacture of catalytic converters and mufflers.

Knitted wire mesh

In conclusion, woven wire mesh is a versatile material that can be used in a variety of applications. Each type of woven wire mesh has its own unique characteristics and properties, making it important to choose the right type of mesh for your specific application. By understanding the different types of woven wire mesh available, you can make an informed decision and ensure that your project is a success.

The above is the introduction of the “What are the different types of woven wire mesh” article, if you have any questions, please leave a message to consult us!