If you are in the market for wire mesh, you may be wondering what the difference is between twill weave and plain weave wire mesh. Both of these types of wire mesh have their own unique characteristics, which can affect their suitability for different applications. we will explain the differences between twill weave and plain weave wire mesh and help you determine which one is right for your needs.

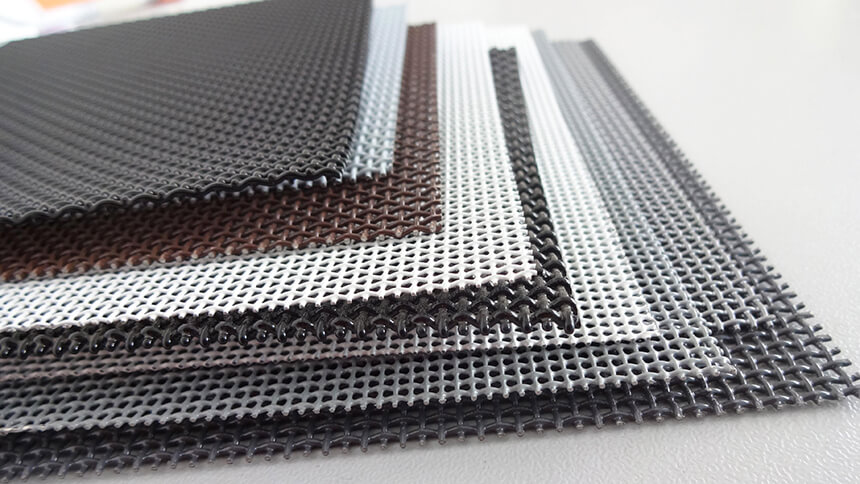

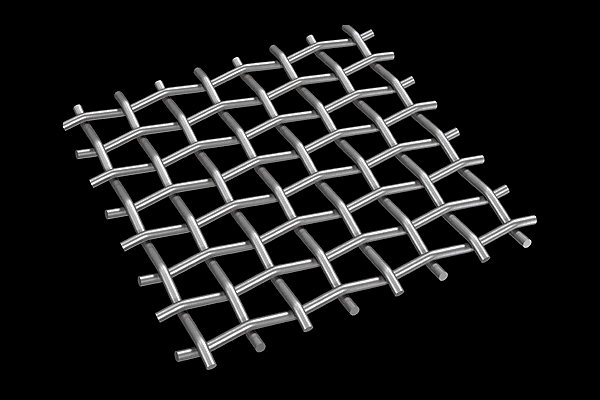

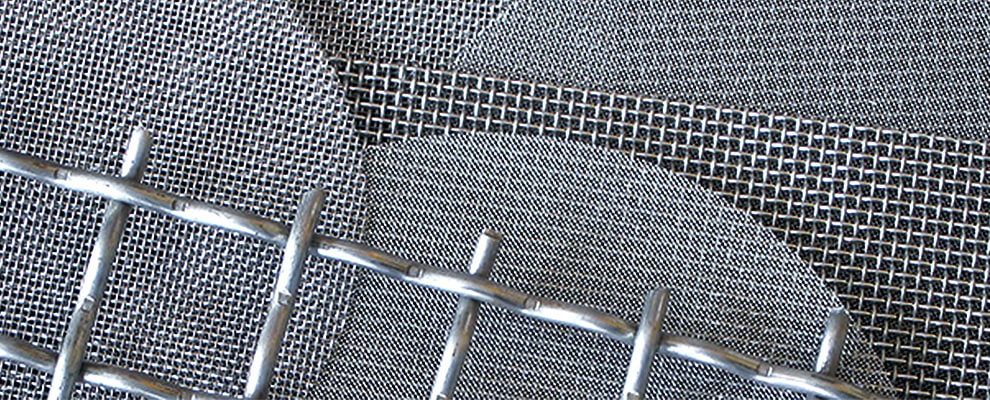

Plain weave wire mesh is the most common type of wire mesh. It is made by weaving wires over and under each other in a simple, alternating pattern. This creates a grid-like pattern of square or rectangular holes that are uniform in size. Plain weave wire mesh is known for its simplicity, durability, and versatility. It is used in a wide range of applications, including filtration, screening, and separation.

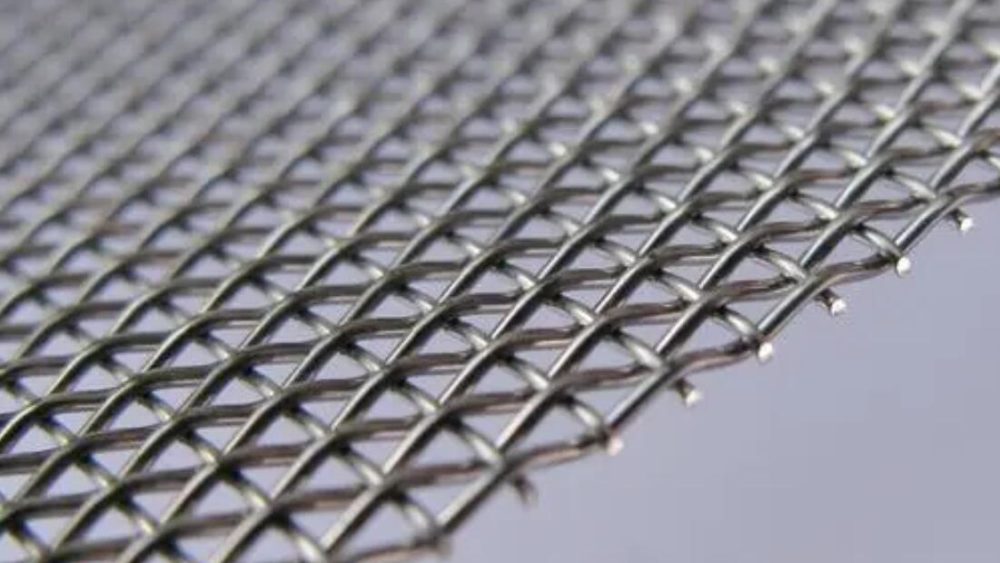

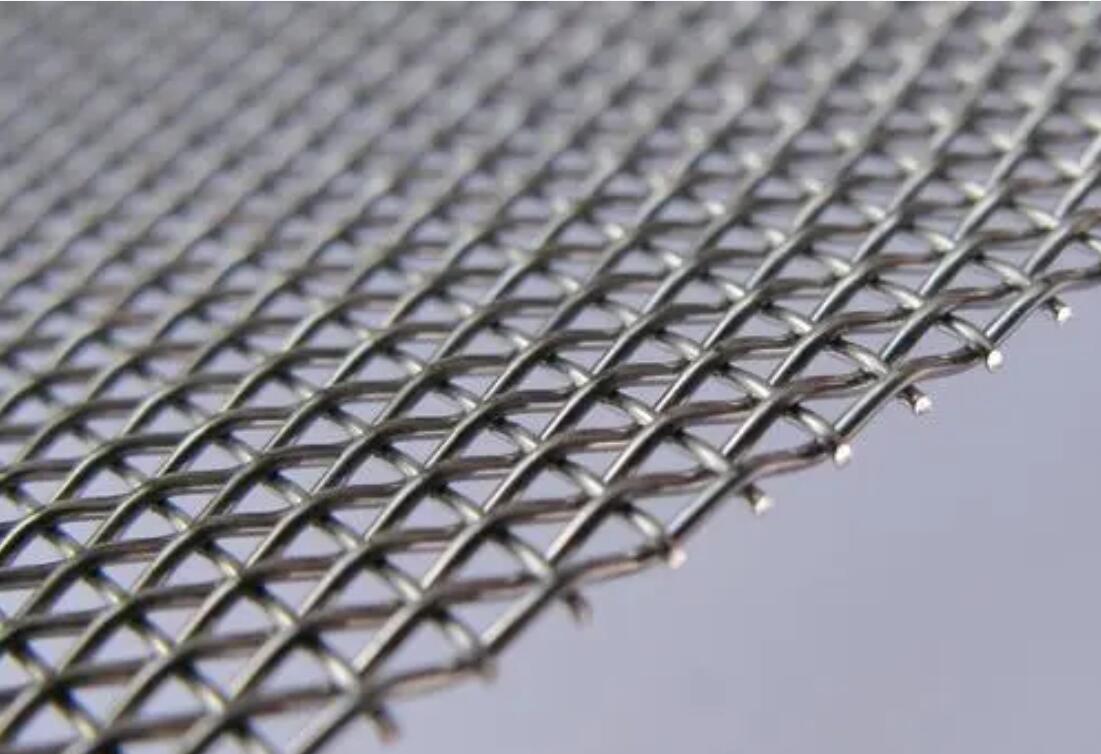

Twill weave wire mesh, on the other hand, is made by weaving wires over and under each other in a more complex pattern. In this pattern, each wire passes over two or more wires and then under two or more wires. This creates a diagonal pattern of interlocking wires that is stronger and more stable than plain weave wire mesh. Twill weave wire mesh is known for its strength, flexibility, and ability to withstand heavy loads. It is used in applications that require high levels of durability and strength, such as industrial filtration and sieving.

One of the main differences between twill weave and plain weave wire mesh is the size of the holes. Twill weave wire mesh typically has smaller holes than plain weave wire mesh, which makes it more suitable for applications that require finer filtration or separation. The diagonal pattern of twill weave wire mesh also makes it less prone to clogging than plain weave wire mesh, which can be a benefit in applications where clogging is a concern.

Another difference between twill weave and plain weave wire mesh is the cost. Twill weave wire mesh is typically more expensive than plain weave wire mesh due to the more complex weaving pattern and the higher quality of materials used. However, the added strength and durability of twill weave wire mesh may make it a worthwhile investment in certain applications where longevity is a concern.

In conclusion, both twill weave and plain weave wire mesh have their own unique characteristics that make them suitable for different applications. Plain weave wire mesh is simple, versatile, and cost-effective, while twill weave wire mesh is strong, flexible, and able to withstand heavy loads. When choosing between twill weave and plain weave wire mesh, it is important to consider your specific application and choose the type of wire mesh that best meets your needs.

The above is the introduction of the “What is the difference between twill weave and plain weave wire mesh” article, if you have any questions, please leave a message to consult us!