Application of Stainless Steel Mesh Screen in Printing Industry

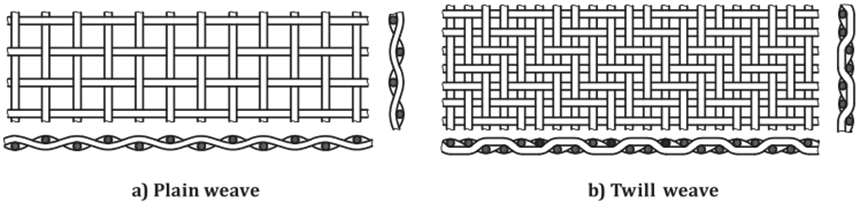

Stainless steel printing screen is also commonly referred to as an ultra-fine screen. It is a special screen used in the printing industry. It adopts plain weave or twill weave technology. As a consumable, it is widely used in the field of screen printing. Corresponding to the stainless steel screen printing technology, in short, the stainless steel screen is tightly stretched on the screen frame, and the screen is made by hand-carved film or photo-chemical plate-making. The ink can only penetrate the graphic part of the screen . the meshes of not the graphics and text, are all blocked and the ink cannot penetrate.

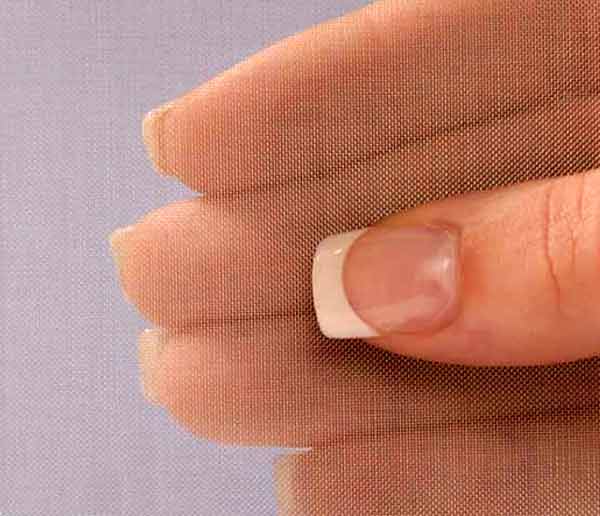

The stainless steel printing screen requires that the mesh opening is square, the angle between the warp and the weft is 90°, and the permeability is high. The wire mesh surface should be flat without joint joints, the wire mesh holes are square and uniform, the friction strength is high, the stretch recovery rate is small, acid and alkali resistance and the strength is not changed due to the influence of ultraviolet rays. Through the use of carefully selected special alloy raw materials and the use of the most advanced weaving technology, the structure of the stainless steel printed screen is particularly compact, while ensuring that the thickness of the screen is within the allowable tolerance range, the tension value is strong, and the degree of stretching of the screen is small, increasing the precision of the wire screen makes it more suitable for high-density printing.

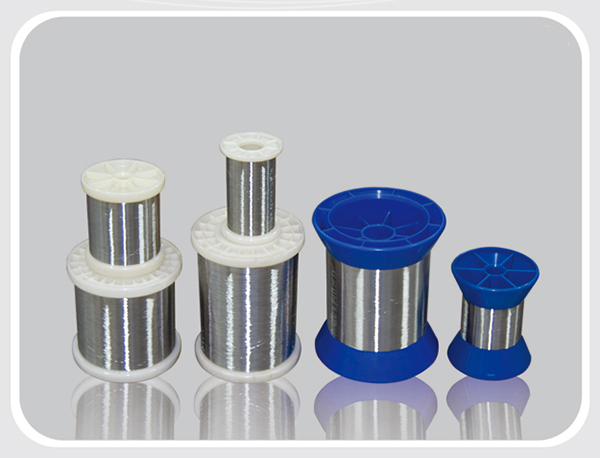

The raw material of stainless steel printing screen

At present, the common stainless steel printing screens on the market can be roughly divided according to quality categories: domestic ordinary stainless steel microwires and imported high-quality wires. Common materials are 304, 304L, 316L, 304N, 304HP, etc.

The most common material is 304.304 is general-purpose stainless steel. It is widely used in the production of equipment and parts that require good comprehensive performance (corrosion resistance and formability); used on stainless steel printing screens, it is more suitable for lower mesh The wire mesh has better strength and anti-fatigue effect.

316 and 316L stainless steel microwires are more suitable in stainless steel wire meshes with higher mesh number, strong plasticity, and good braiding effect.

304N stainless steel wire is a kind of stainless steel microwire containing nitrogen. Nitrogen is added to improve the strength of the steel. It is suitable for the production of stainless steel screens with higher tension.

The quality requirements of stainless steel microwire materials: high-quality wire, high precision, high strength, not easy to break, good plasticity and stability, and other advantages.

Principle of stainless steel screen printing

Screen printing is composed of five major elements, namely screen, doctor blade, paste, table, and substrate. The basic principle of screen printing is to use the basic principle of screen mesh part through mesh paste and non-graphic part mesh impermeable paste for printing. During printing, pour the paste at one end of the screen, and apply a certain pressure to the paste part of the screen with a scraper, while moving toward the other end of the screen. The ink is squeezed onto the substrate from the mesh of the graphic part by the squeegee while moving. Due to the viscosity of the paste, the imprint is fixed within a certain range. During the printing process, the squeegee is always in line contact with the screen plate and the substrate. The contact line moves with the movement of the blade. Due to the difference between the screen and the substrate Keep a certain gap between them, so that the screen during printing generates a reaction force to the scraper through its own tension. This reaction force is called the rebound force. Due to the resilience, the screen and the substrate are only in contact with the mobile line, while the other parts of the screen are detached from the substrate, ensuring the dimensional accuracy of the printing and avoiding dirty substrates. When the squeegee is scraped across the entire printing area and lifted, the screen is also separated from the substrate, and the table returns to the loading position, which is a printing stroke.

Features of the stainless steel printing screen

The stainless steel wire mesh is resistant to acids and alkalis, resistant to abrasion, and strong in tension. It also has the characteristics of high tension, ultra-high precision, low extension, high yield point, high abrasion resistance, no static electricity, and heat resistance.

High tension: the tension is higher than polyester wire mesh, and the stability is high

Ultra-high precision: the opening is very uniform and the error rate is extremely small

Low elongation: under high tension, the wire mesh extension is very small

High yield point: under extremely high tension, will not lose elasticity due to deformation

High abrasion resistance: the steel wire has excellent abrasion resistance, far exceeding the fiber

No static: prevent static and ensure the printing effect

Good heat resistance: suitable for hot-melt inks, is a special point of steel mesh

Good solvent resistance: prevent various solvents from damaging the screen and ensure printing safety.

Further-processing of stainless steel printing screen

In terms of quality requirements for printed screens, it is very important that the screen surface must be flat and tidy without stains; stains that are accidentally generated during the production process require fine decontamination treatment.

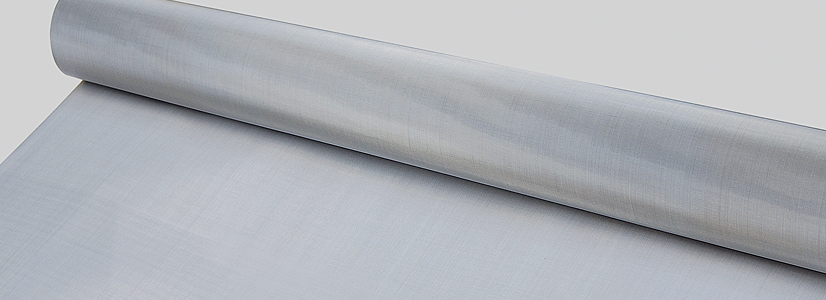

The stainless steel printing screen is an ultra-thin printing screen. The thickness of the screen is a determinant of controlling the amount of printing ink. Changing the thickness of the printing screen based on the original screen is a very precise work in the post-processing process, mainly through the screen.

The calendering process is to improve the basic performance of the wire mesh, and firmly prevent the mesh deformation, uneven thickness of the mesh surface, creases, and other undesirable phenomena. Also, the rolling process can make the wire mesh more smooth and bright.

Application characteristics of stainless steel screen in screen printing

Stainless steel screen printing has become the most ideal screen material for the screen printing industry, especially the electronics industry.

In high-precision series products, it is often used to print high-definition and high-quality graphics, especially suitable for PCB circuit board printing, microelectronics (resistance, capacitance, inductance), photoelectric display (LCD, VFD, PDP), liquid crystal display, Vacuum display, solar cell, insulating oil, solder resist oil, solder paste, membrane switch, instrument dial, glass-ceramic, panel dial and so on. In recent years, silk screen printing has also been widely used in packaging, decoration, advertising, posters, etc. The stainless steel screen has the following characteristics in printing.

1. Thick ink layer and strong coverage

The thickness of the ink layer of stainless steel screen offset printing and relief printing is only a few microns, the thickness of the gravure printing is about 12um, the thickness of the ink layer of the flexographic (aniline) screen printing is 10um, and the thickness of the ink layer of the stainless steel screen printing far exceeds the above The thickness of the ink layer can reach 30-100um. Special printed circuit board stainless steel wire mesh thickness can reach 1000um. Use foaming ink to make Braille ideas. The thickness of the ink layer after foaming can reach 300um. Therefore, the covering ability of the ink is particularly strong. It can be used for pure white printing on black paper or metal plates. Besides, the thick ink layer can be used to print various industrial products such as circuit boards. The stainless steel screen printing ink layer is thick, and the three-dimensional sense of printed graphics is strong, which is comparable to other printing methods. If the general printing method uses white to cover the underlying background, it is necessary to copy three to four times in the same part, and stainless steel screen printing and screen printing can be completed only once. Due to the thick ink layer, the hand feels good and the three-dimensional sense is strong. , So it is widely used. Of course, the thickness of the ink layer can also be controlled. Stainless steel screen printing can be used not only for monochrome printing but also for color registration and screen color printing.

2. you can use a variety of ink printing

Stainless steel screen printing has the characteristics of missing printing, so it can use any kind of ink and paint, such as oily, water-based, synthetic resin type, powder type, and other inks, under different conditions, for any material can meet the various Printing for various purposes. Screen printing inks all kinds of coatings, other printing requires the pigment particle size of various inks to be fine, and stainless steel screen printing can be used as long as the inks and coatings that can pass through the mesh of the stainless steel screen can be used. All the inks for screen printing are wide. Beyond the definition of ordinary ink. There are pastes, adhesives, or solid powders. Therefore, screen printing inks are sometimes collectively referred to as “printing materials”

3. The layout is soft and the printing pressure is small

The stainless steel screen printing plate is soft and flexible, and the printing pressure is small, so it can not only print on soft materials such as paper and textiles, but also on high-hardness boards such as glass, metals, and hard plastics that are easily damaged. Or print directly on the surface of the molded object.

4. strong light resistance

Stainless steel screen printing has the characteristics of leaking brushes, so it can use a variety of staining agents and various colors, and it can also use pigments with coarse particles. Therefore, it can put light-resistant pigments and fluorescent pigments easily. Into the ink, so that the graphics of the printed matter can always maintain the gloss without being affected by the temperature and sunlight, and can even shine at night. The preparation of stainless steel screen printing ink is simple. For example, light-resistant materials can be placed directly in the ink to prepare. Since the light resistance of silk-screen products is stronger than other types of printed products, it is more suitable for outdoor advertising and signage.

5. stainless steel screen printing is flexible and diverse

Stainless steel screen printing, like other types, can be mass-produced industrially. At the same time, it has the characteristics of convenient plate making, cheap price, diverse printing methods, flexible, and easy to master technology, so it has developed rapidly in recent years.

Specification table of stainless steel printing mesh

| Mesh/Inch | Wire Diameter | Aperture | Open Area(%) | Mesh Thickness (μm) | Mesh Thickness after Calandered (μm) |

| (μm) | (μm) | ||||

| 80 | 50 | 268 | 71 | 110-115 | 88-90 |

| 80 | 90 | 228 | 52 | 198-207 | 168-170 |

| 80 | 120 | 198 | 39 | 276-288 | 228-230 |

| 100 | 100 | 154 | 36.8 | 230-240 | 188-190 |

| 120 | 80 | 132 | 39 | 184-192 | 148-150 |

| 150 | 60 | 109 | 41.7 | 158-162 | 102-140 |

| 165 | 35 | 119 | 60 | 108-110 | 77-81 |

| 165 | 45 | 109 | 50.1 | 95-104 | 78-80 |

| 165 | 50 | 104 | 45.6 | 110-115 | 88-90 |

| 180 | 45 | 96 | 46.4 | 99-104 | 78-80 |

| 180 | 50 | 91 | 42 | 115-120 | 88-90 |

| 200 | 40 | 87 | 46.9 | 81-82 | 68-76 |

| 200 | 50 | 77 | 37 | 115-120 | 88-90 |

| 250 | 30 | 72 | 49.7 | 63-64 | 50-59 |

| 250 | 35 | 67 | 43 | 76-78 | 59-66 |

| 250 | 40 | 62 | 49.7 | 82-86 | 50-80 |

| 270 | 35 | 59 | 39.4 | 76-80 | 58-70 |

| 290 | 20 | 68 | 41.7 | 43-44 | 29-35 |

| 300 | 30 | 55 | 38 | 66-68 | 40-59 |

| 325 | 23 | 55 | 49.8 | 49-53 | 38-39 |

| 325 | 28 | 50 | 41.2 | 63-64 | 50-55 |

| 350 | 25 | 48 | 43 | 52-54 | 41-50 |

| 400 | 23 | 41 | 40.7 | 50-54 | 35-48 |

| 400 | 18 | 46 | 51.3 | 36-40 | 28-30 |

Hightop® Metal Mesh provides high-quality printing quality stainless steel wire mesh. All stainless steel wire meshes are subject to rigorous inspection and will be sent to customers after passing the inspection. Our stainless steel wire mesh is mainly sold to the United States, Europe, Latin America, Southeast Asia, Australia, and other regions, and has been well received by customers.

If you are looking for high-quality printing quality stainless steel wire mesh or want to know more about screen printing quality stainless steel wire mesh, please click here to send us your inquiry.