Stainless steel wire mesh has several woven types, as we all know, like plain weave, twill weave, dutch weave, plain dutch weave, twill dutch weave. Now i explanation of these woven types:

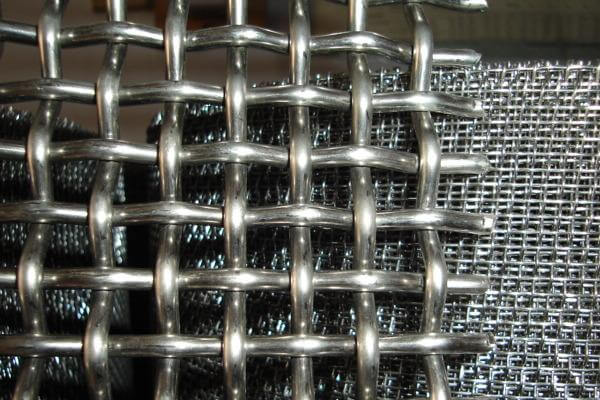

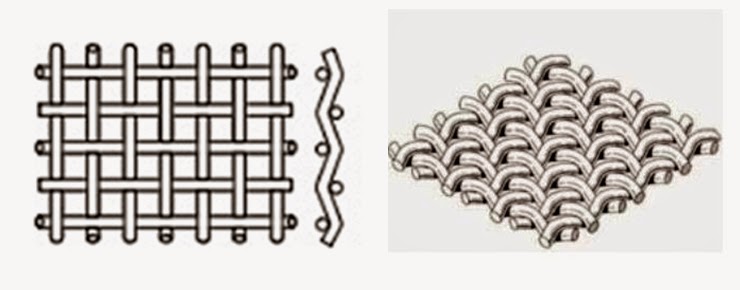

Plain Weave

plain weave is the most common weave types , it is the most popular woven types, It has an extremely wide range of applications. Plain weave means each wire alternates – first going under one wire, then going over the next wire. Each warp wire (wire running-parallel to length of cloth) passes alternately over and under the wires running travel through the cloth (fill or shoot wires) at 90 degree angles.

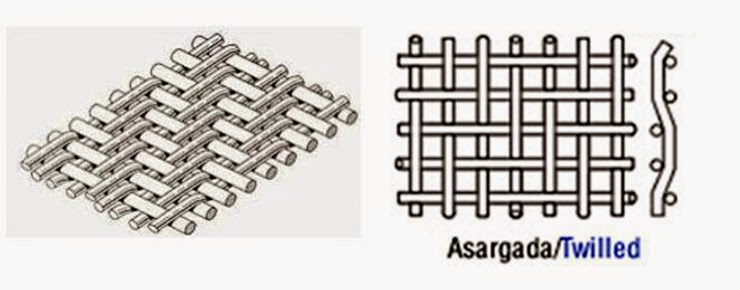

Twill Weave

Twill weave stainless steel wire mesh is woven by passing the shute wire over and under two warp wires, creating a sturdier weave. This weave allows for the use of heavier wires, producing a stronger wire mesh. This woven types has a wide application capable of supporting greater loads and finer filtrations.

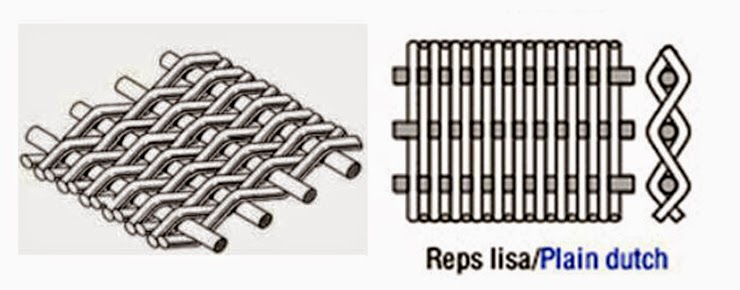

Plain Dutch Weave

Stainless steel wire mesh plain dutch weave wire mesh is woven using two sizes of wire. Smaller wires, as small as micron size, are used in the shute direction and are woven with a larger warp wire. The smaller wires are woven tightly together, providing a tight mesh for filtering. The larger wire provides strength to the mesh. The primary uses of this wire cloth are filtration and separation of liquid and slurry products.

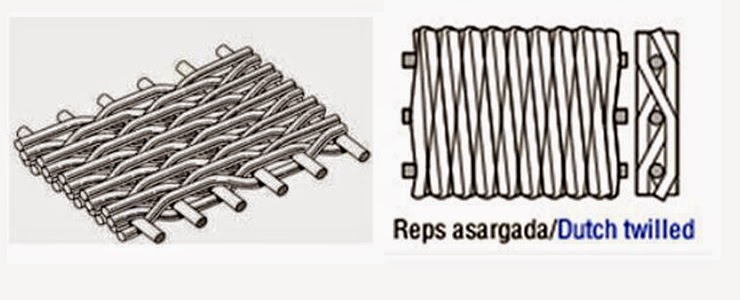

Twill Dutch Weave

Twill dutch weave stainless steel wire mesh combines dutch and twill weaving to provide a fine mesh filtering cloth. Shute wires are passed over and under two warp wires, providing a tight, fine filter with tapered openings. The weaving process allows for the use of very fine wires, to micron size, producing filtering mesh for gas and liquid applications.