Duplex Stainless Steel Wire Mesh Quick Details:

- Usage: Heat exchanger, Pressure vessels etc.

- Material: 2101,2205,2507, Zeron 100, LDX 2101

- MOQ: 1 roll

- Woven style: Plain and Twill Weave

- Mesh :3-500Mesh

- Diameter: 0.025mm-2.2mm

- Roll Width: 0.1-1.5m

- Roll Length: 10-100m

- Packaging Details: inner kraft paper, outside plastic cloth, put into wooden pallet or case

- Delivery Time: 5 days for stock material

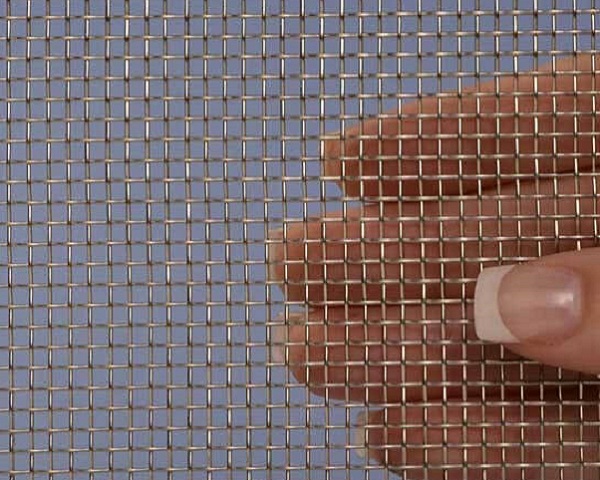

Duplex Stainless Steel Wire Mesh

Features

- Excellent resistance to crevice corrosion, pitting, stress related corrosion cracking

- Excellent resistance to erosion and corrosion fatigue

- High durability and resistance to chloride stress corrosion cracking

- Increased thermal conductivity

- Higher energy absorption

- Excellent resistance to sulfide stress corrosion

- Has reduced thermal expansion while having increase heat conductivity versus austenitic steels

- Excellent weld and workability

Industrial Applications

- Cargo tanks for piping and welding consumables used for chemical tankers

- Desalination plants pipes and heat exchangers

- Gas and oil tube and pipes, heat exchangers

- Usage for pressure vessels for transports of chemicals

- Usage on rotors, fans, or other equipment that has high corrosion where the fatigue strength can be used

Duplex Stainless Steel Wire Mesh Specification

| Mesh Inch | S.W.G | Aperture (mm) | Wire Diameter (mm) | Weight (Kg/m2) | Effective (%) | ||||||

| 3mesh | 14 | 6.27 | 2.2 | 62 | 7 | ||||||

| 3mesh | 18 | 7.25 | 1.219 | 70 | 2.5 | ||||||

| 3.5mesh | 20 | 6.34 | 0.914 | 66 | 1.8 | ||||||

| 4mesh | 16 | 4.72 | 1.63 | 58 | 5 | ||||||

| 4mesh | 20 | 5.45 | 0.914 | 76 | 2.1 | ||||||

| 4.5mesh | 22 | 4.93 | 0.711 | 71 | 1.2 | ||||||

| 5mesh | 18 | 3.86 | 1.22 | 57 | 3.6 | ||||||

| 5mesh | 22 | 4.36 | 0.711 | 76 | 1.3 | ||||||

| 6mesh | 18 | 3.04 | 1.22 | 50 | 4.3 | ||||||

| 6mesh | 22 | 3.52 | 0.711 | 63 | 1.6 | ||||||

| 8mesh | 20 | 2.26 | 0.91 | 43 | 3.2 | ||||||

| 8mesh | 24 | 2.5 | 0.559 | 67 | 1.5 | ||||||

| 10mesh | 20 | 1.63 | 0.91 | 41 | 4 | ||||||

| 10mesh | 26 | 2.08 | 0.46 | 67 | 1.1 | ||||||

| 12mesh | 22 | 1.41 | 0.71 | 43 | 2.9 | ||||||

| 12mesh | 26 | 1.74 | 0.457 | 68 | 1.4 | ||||||

| 14mesh | 26 | 1.36 | 0.46 | 57 | 1.4 | ||||||

| 16mesh | 28 | 1.21 | 0.376 | 55 | 1.2 | ||||||

| 18mesh | 30 | 1.1 | 0.315 | 60 | 0.85 | ||||||

| 20mesh | 30 | 0.95 | 0.315 | 58 | 0.95 | ||||||

| 22mesh | 32 | 0.88 | 0.274 | 57 | 0.8 | ||||||

| 24mesh | 32 | 0.78 | 0.274 | 55 | 0.85 | ||||||

| 26mesh | 32 | 0.74 | 0.274 | 51 | 0.7 | ||||||

| 28mesh | 34 | 0.67 | 0.234 | 50 | 0.75 | ||||||

| 30mesh | 34 | 0.61 | 0.234 | 48 | 0.8 | ||||||

| 32mesh | 34 | 0.56 | 0.234 | 50 | 0.84 | ||||||

| 36mesh | 34 | 0.47 | 0.234 | 45 | 0.95 | ||||||

| 38mesh | 36 | 0.48 | 0.193 | 46 | 0.7 | ||||||

| 40mesh | 36 | 0.44 | 0.193 | 50 | 0.8 | ||||||

| 50mesh | 38 | 0.36 | 0.152 | 46 | 0.58 | ||||||

| 60mesh | 40 | 0.3 | 0.122 | 50 | 0.45 | ||||||

| 80mesh | 40 | 0.198 | 0.12 | 44 | 0.58 | ||||||

| 100mesh | 42 | 0.154 | 0.1 | 37 | 0.5 | ||||||

| 120mesh | 44 | 0.13 | 0.081 | 40 | 0.39 | ||||||

| 130mesh | 45 | 0.125 | 0.07 | 41 | 0.325 | ||||||

| 140mesh | 45 | 0.111 | 0.07 | 38 | 0.35 | ||||||

| 150mesh | 46.5 | 0.115 | 0.055 | 48 | 0.206 | ||||||

| 160mesh | 46 | 0.097 | 0.61 | 32 | 0.3 | ||||||

| 170mesh | 47 | 0.09 | 0.05 | 41 | 0.213 | ||||||

| 180mesh | 47 | 0.09 | 0.051 | 410 | 0.24 | ||||||

| 190mesh | 47 | 0.083 | 0.051 | 40 | 0.24 | ||||||

| 200mesh | 48 | 0.086 | 0.041 | 46 | 0.17 | ||||||

| 220mesh | 48 | 0.074 | 0.041 | 41 | 0.19 | ||||||

| 240mesh | 48 | 0.065 | 0.041 | 39 | 0.2 | ||||||

| 250mesh | 48 | 0.061 | 0.041 | 38 | 0.22 | ||||||

| 260mesh | 48 | 0.057 | 0.041 | 34 | 0.22 | ||||||

| 280mesh | 49 | 0.06 | 0.031 | 31 | 0.14 | ||||||

| 300mesh | 49 | 0.054 | 0.031 | 40 | 0.15 | ||||||

| 320mesh | 49 | 0.048 | 0.031 | 39 | 0.16 | ||||||

| 350mesh | 49 | 0.042 | 0.031 | 36 | 0.16 | ||||||

| 400mesh | 50 | 0.0385 | 0.025 | 39 | 0.013 | ||||||

| 450mesh | 50 | 0.0314 | 0.025 | 37 | 0.14 | ||||||

| 500mesh | 50 | 0.0258 | 0.025 | 35 | 0.156 |