Have you ever wondered how mining companies efficiently separate valuable minerals from mountains of raw rock? Or how they manage to sort, grade, and refine different types of materials with such precision? Behind this efficiency lies an essential but often overlooked component—mine screen mesh.

Mine screen mesh plays a critical role in every stage of the mining process, from ore extraction to waste management. This durable and versatile material ensures accurate screening, better processing efficiency, and reduced operational costs.

Why does this simple mesh make such a big impact in such a complex industry? Let’s take a deeper look.

What Is Mine Screen Mesh?

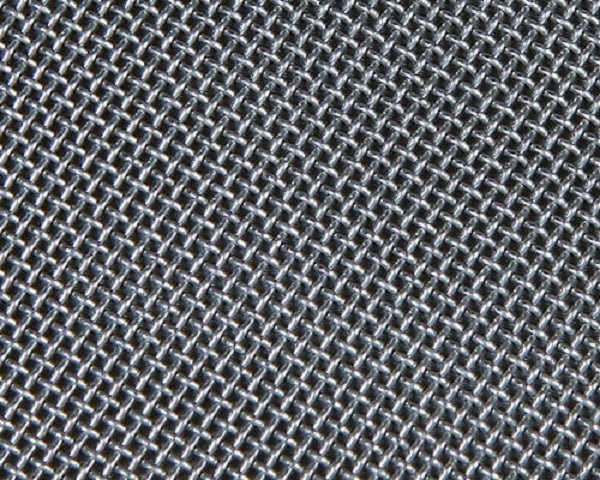

Mine screen mesh—also known as mining screen or crimped wire mesh—is typically used for preliminary screening and sizing of ores. Its job is to separate crushed materials into fractions of different sizes, enabling further processing.

It is usually made from high carbon steel or stainless steel, depending on the specific application. High carbon steel offers greater strength and wear resistance, making it ideal for high-impact environments. Among them, 65Mn steel stands out for its balance of strength and cost-effectiveness. On the other hand, stainless steel (301, 304, 316, etc.) provides superior corrosion resistance, making it ideal for use in environments exposed to moisture or chemicals.

The mesh comes in various forms, such as:

Square or rectangular openings

Interlocking or double crimp designs

Hooked edges for better installation

Core Applications of Mine Screen Mesh in the Mining Industry

Ore Dressing and Size Separation

After large rocks are broken down by crushers, mine screen mesh is used to classify the ore into different sizes. This step is essential before the ore can undergo flotation, magnetic separation, or leaching.

Efficient size grading not only increases the yield of valuable minerals but also protects downstream equipment from overload and damage.

Slag and Tailings Recycling

The mining process often leaves behind slag or tailings—waste material that still contains residual minerals. With proper re-screening using mine screen mesh, companies can recover these valuable particles. This contributes to better resource utilization and environmental protection.

This process usually involves:

Crushing the slag into finer particles

Re-screening using high-strength mesh

Recovering reusable ore from waste

Sand and Gravel Aggregate Production

In the sand and gravel industry, mine screen mesh is used alongside crushers, feeders, and conveyors to separate large aggregates from fine sand. The mesh helps ensure consistent quality of the final product, whether it’s for road construction, concrete production, or landscaping.

Its advantages include:

Superior impact resistance

Consistent particle sizing

Compatibility with multiple types of screening equipment

Manufactured Sand Production

Mining screens are also used in crushing operations to produce manufactured sand. Stones like granite, basalt, and diorite are processed through coarse, medium, and fine crushing. After each crushing stage, mine screen mesh ensures proper particle sizing to improve the quality of the final sand product.

This makes the mesh critical for:

Ensuring fine consistency of artificial sand

Reducing waste material in the production cycle

Improving the strength and durability of construction materials

Construction Waste Management

When buildings are demolished, large volumes of mixed debris are generated. Mine screen mesh helps in recycling this waste into usable construction material by separating reusable aggregates from dust and debris.

Using mesh screens in this context:

Reduces landfill pressure

Supports sustainable construction practices

Offers economic benefits through material reuse

Why Choose Woven Wire Mesh for Mine Screen Mesh?

The use of woven wire mesh in mine screen mesh offers several key advantages:

- Excellent flexibility and adaptability, making it suitable for various screening equipment and ore types

- Precise aperture sizes, ensuring accurate particle separation and consistent screening results

- Superior wear resistance, especially when using high carbon steel or 65Mn material

- Easy installation and replacement due to its standard sizes and lightweight nature

Woven wire mesh is also available in a range of opening sizes, wire diameters, and weaving styles (such as square, rectangular, double crimped, and flat-top crimp). This allows for customization based on the specific demands of your screening operation. Surface treatments like galvanization or stainless steel construction further enhance corrosion resistance and longevity.

From ore separation to environmental management, mine screen mesh made from woven wire is a vital component in the mining industry. Its ability to withstand harsh conditions, deliver precise grading, and support sustainable practices makes it indispensable.

By investing in high-quality woven wire mine screen mesh, mining operations can achieve greater productivity, reduce downtime, and maximize resource recovery. Whether you’re managing a quarry, processing plant, or recycling center, choosing the right mesh makes all the difference.

Get Quote

We would like to hear from you. Please get in touch with us by filling out the contact form below, we will get back to you shortly.

Comments are closed.