Stainless Steel Woven Wire Mesh

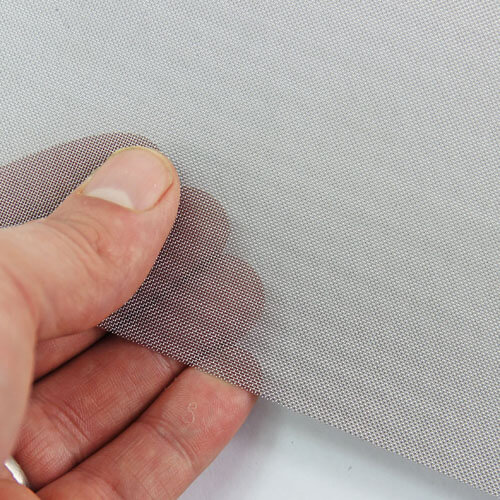

Extra Fine Stainless Wire Mesh

We manufacture and supplies ultra fine stainless wire mesh which conforms to the standard ASTM E2016 and ISO 9044, the hole size is from 0.02-0.2 mm (0.0008-0.0078 in.)

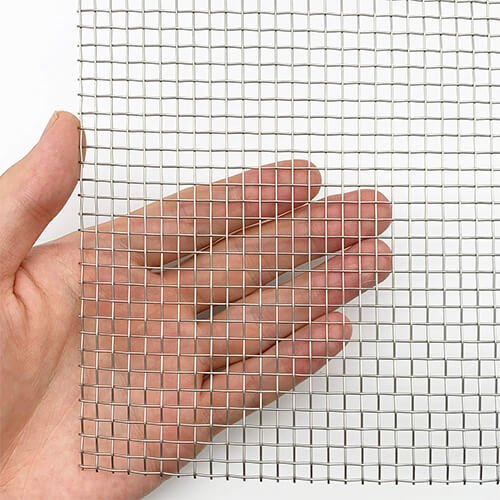

Stainless Steel Coarse Mesh

We are a manufacturer and supplier which can offer you stainless steel coarse mesh, the hole size is from 0.5-2 mm (0.020-0.079 in.)

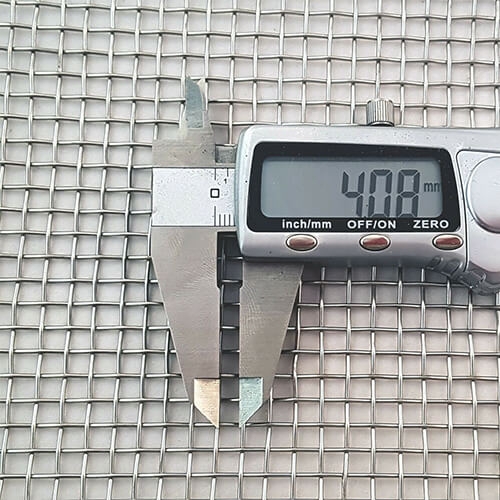

Heavy Duty Mesh

We are a manufacturer and supplier which can offer you coarse mesh, the hole size is from 2.0-23 mm (0.079-0.9 in.)

Stainless Woven Wire Mesh Quick Details:

- Material: SS 201, 202, 304, 304L, 316, 316L, 321, 430, etc.

- Types of Weave: Plain Weave, Twill Weave and Dutch Weave

- Mesh count: 1-635 mesh

- Diameter: 0.0008″-0.08″ (0.02-2.0 mm)

- Standard width/roll: 3 ft (36 in.), or 1 m in metric, customization available

- Standard length/roll: 100 ft (1,200 in.), or 30m in metric, customization available

- Packing: inner kraft paper, outside plastic cloth, put into wooden pallet or case

- Use: Filters, sieve, window screen, insect screen, chemical industry, mine industry, paper-making, etc.

- Delivery Time: 5 days for stock material

Hightop offers quality stainless steel wire mesh, wire cloth and screen. Our company manufactures and supplies metal mesh products to meet and exceed our client’s specific requirements, reducing costs while increasing production efficiency. We have a full range of 304 and 316 stainless wire mesh products available for immediate shipping and we can supply our clients with extra wide wire cloth products of up to 240″ wide and extra-long rolls of up to 2000″. Hightop’s wire mesh products comply with the ASTM E2016, ASTM E2814 and ISO 9044 as our minimum standard.

STAINLESS WOVEN WIRE MESH SPECIFICATIONS

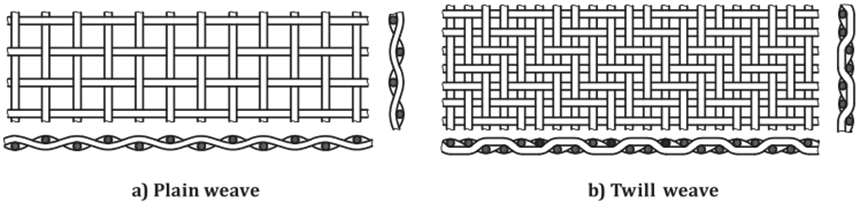

Plain Weave & Twill Weave

Plain Weave is the the most common and simplest of all weaves with apertures from 10.7mm to 0.05mm, the diameter is almost the same for both the warp and the weave. It is composed of weft wire warped alternately above and below creating a wire mesh. Plain weave is also the most economical, applications including filtration, sifting, sieve and safety equipment, etc.

Twill Weave

For heavier needs, the twill weave is recommended. The shute wire is passed above and under two warp wires ensuring that the weave is sturdier as this produces a stronger and more durable mesh. The warp and weft have the same diameters thus creating a close diagonal pattern. This type of pattern is mostly used for filtration.

Applications:

- Sizing

- Separation and Filtration

- Sifting of particles

- In safety and equipment protection

- Aerospace

- Automotive

- Construction

- Oil and Gas

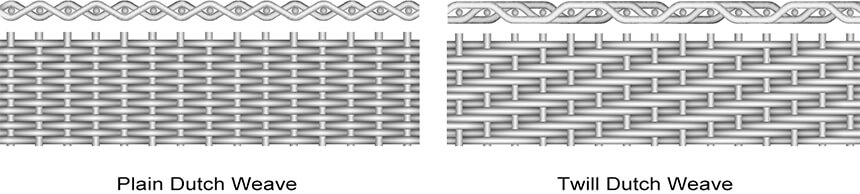

Stainless Steel Wire Mesh – Dutch Weave

Dutch weave also known as “Hollander weave mesh”, is ideal for high-pressure filtration as this is stronger and more durable than plain weave mesh. The Dutch uses larger diameters and each weave pattern is made up of a limited number of warp wires, which are interwoven with weft wires creating a cloth that can withstand strong pressure. This type of mesh is usually used for liquid filtration for petrochemical, aerospace, pharmaceutical and even on wastewater treatment facilities.

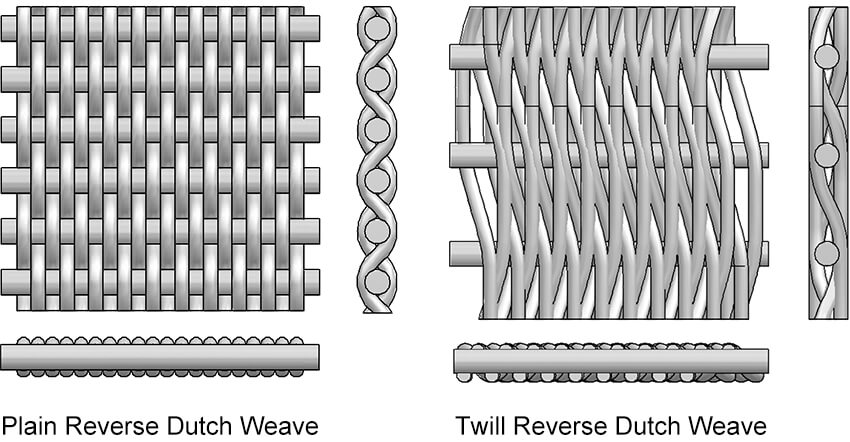

Reverse Plain Dutch Weave (RPD)

Reverse Plain Dutch Weave makes use of two different sizes of wires in weaving. The smaller wires are warped against a large shute wire and woven as closely as possible to create a finer and tight mesh cloth. The larger wire is used to strengthen and support the whole mesh.

Twilled Reverse Dutch Weave (TRD)

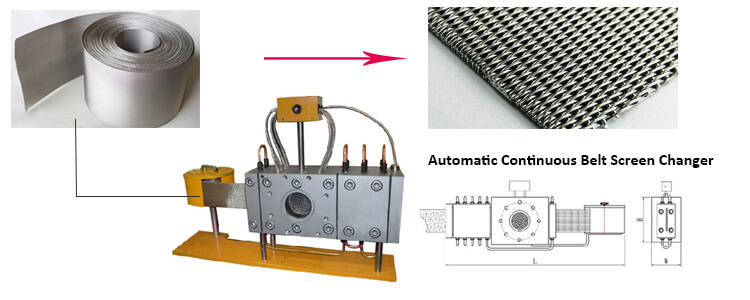

Twilled Reverse Dutch Weave on the other hand makes use of the Plain Dutch and twill weaving to create a fine mesh cloth. The fine wires are tightly woven together making this ideal for filtration of gas and other liquid applications. Possessing high resistance to corrosion and high temperature, the Reverse Dutch weave mesh is the ideal filtering mesh (e.g. Extruder Screens), with smooth surface and resistant to deformation and hardness. It’s one of the best meshes for industrial applications that require separation of liquid and slurry matter.

Extruder Screen Specifications

- Width: 97mm, 120mm, 127mm, 130mm, 133mm, 150mm, 156mm, 280mm and 400mm, etc.

- Length: 10m – 30m;

- Material: SS 201, SS 302, SS304, SS304L, SS316, SS316L, etc.

- Plain/Twill Weave

-

Plain Weave & Twill Weave

Plain Weave is the the most common and simplest of all weaves with apertures from 10.7mm to 0.05mm, the diameter is almost the same for both the warp and the weave. It is composed of weft wire warped alternately above and below creating a wire mesh. Plain weave is also the most economical, applications including filtration, sifting, sieve and safety equipment, etc.

Twill Weave

For heavier needs, the twill weave is recommended. The shute wire is passed above and under two warp wires ensuring that the weave is sturdier as this produces a stronger and more durable mesh. The warp and weft have the same diameters thus creating a close diagonal pattern. This type of pattern is mostly used for filtration.

Applications:

- Sizing

- Separation and Filtration

- Sifting of particles

- In safety and equipment protection

- Aerospace

- Automotive

- Construction

- Oil and Gas

- Dutch Weave

-

Stainless Steel Wire Mesh – Dutch Weave

Dutch weave also known as “Hollander weave mesh”, is ideal for high-pressure filtration as this is stronger and more durable than plain weave mesh. The Dutch uses larger diameters and each weave pattern is made up of a limited number of warp wires, which are interwoven with weft wires creating a cloth that can withstand strong pressure. This type of mesh is usually used for liquid filtration for petrochemical, aerospace, pharmaceutical and even on wastewater treatment facilities. - Reverse Dutch Weave

-

Reverse Plain Dutch Weave (RPD)

Reverse Plain Dutch Weave makes use of two different sizes of wires in weaving. The smaller wires are warped against a large shute wire and woven as closely as possible to create a finer and tight mesh cloth. The larger wire is used to strengthen and support the whole mesh.

Twilled Reverse Dutch Weave (TRD)

Twilled Reverse Dutch Weave on the other hand makes use of the Plain Dutch and twill weaving to create a fine mesh cloth. The fine wires are tightly woven together making this ideal for filtration of gas and other liquid applications. Possessing high resistance to corrosion and high temperature, the Reverse Dutch weave mesh is the ideal filtering mesh (e.g. Extruder Screens), with smooth surface and resistant to deformation and hardness. It’s one of the best meshes for industrial applications that require separation of liquid and slurry matter.

Extruder Screen Specifications

- Width: 97mm, 120mm, 127mm, 130mm, 133mm, 150mm, 156mm, 280mm and 400mm, etc.

- Length: 10m – 30m;

- Material: SS 201, SS 302, SS304, SS304L, SS316, SS316L, etc.

Get Quote

We would like to hear from you. Please get in touch with us by filling out the contact form below, we will get back to you shortly.